To begin, we enter the realm of diamond seed selection. Just like in nature, where diamonds are formed under extreme heat and pressure deep within the Earth, scientists aim to replicate these conditions in a controlled environment. They start by carefully selecting a high-quality diamond seed, which serves as the foundation for the CVD Lab-grown diamond.

Now, brace yourself for the next step: the Chemical Vapor Deposition (CVD) method. In this technique, a tiny diamond seed is placed in a specialized chamber, which is then filled with a carbon-rich gas, such as methane. The chamber is heated to extreme temperatures, sometimes exceeding 1,500 degrees Celsius (2,732 degrees Fahrenheit).

The gas molecules containing carbon break down in the heat, releasing carbon atoms. These carbon atoms then settle on the diamond seed, layer by layer, slowly building up the diamond crystal structure. This process is similar to the way natural diamonds form over millions of years, except it is accelerated within a controlled environment.

During this growth process, scientists closely monitor and control various factors, such as temperature, pressure, and gas composition. By carefully adjusting these parameters, they can influence the diamond’s quality, color, and other characteristics.

As time passes, the diamond seed continues to grow, with carbon atoms attaching themselves to the surface of the seed. The process is typically carried out for several weeks, or even months, allowing the CVD Lab-grown diamond to reach its desired size.

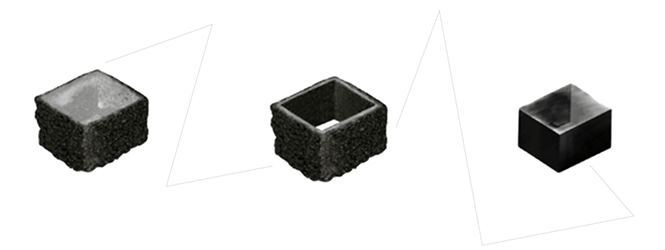

Once the CVD lab-grown diamond has reached its desired size, it is carefully extracted from the growth chamber. However, at this stage, it appears rough and unpolished. To unlock its true brilliance, skilled diamond cutters take over.

These artisans use traditional cutting and polishing techniques to transform the rough CVD Lab-grown diamond into a dazzling gem. Like natural diamonds, the diamond is shaped and faceted precisely to maximize its sparkle. The final result is a brilliant, scintillating CVD Lab-grown diamond ready to be set into jewellery or used in various industrial applications.

CVD Lab-grown diamonds undergo a grading process similar to natural diamonds, although there may be some differences in the specific criteria considered. The Gemological Institute of America (GIA), a renowned gemological laboratory, is at the forefront of diamond grading and certification, encompassing both natural and CVD Lab-grown diamonds.

During the grading process, various factors are evaluated to assess the quality and characteristics of the diamond. These factors include the diamond’s 4Cs: Carat Weight, Colour, Clarity, and Cut.

CVD Lab-grown diamonds undergo a detailed inspection by gemologists to ensure they meet quality standards. This involves examining the diamond for imperfections, verifying its specifications, and making any necessary adjustments or polishing.

These processes ensure that CVD lab-grown diamonds meet desired quality standards and offer reliable and consistent quality to consumers.

Throughout the manufacturing process, quality control measures are implemented to ensure consistent quality. This includes monitoring parameters, sampling and testing, equipment calibration, and maintaining traceability and documentation.